Fraunhofer ISE

Fraunhofer ISE Showcases Shingle Solar Cells, Integrated Photovoltaics, Power Electronics, Solar Forecasting and Battery Technology at Intersolar Europe

This year’s Intersolar Europe in Munich will see Fraunhofer ISE exhibit shingle solar cells and modules designed to integrate photovoltaics into buildings and vehicles, as well as sensors optimized to enable more accurate solar radiation forecasting. The latest developments in power electronics and battery technology, in addition to solar cell manufacturing technology and defect measurement for solar modules, will augment the range of exhibits presented by Fraunhofer ISE at its booth in hall A1.540. Completing the institute’s range of services at the leading exhibition for solar technology will be numerous presentations and workshops as part of the accompanying program and the conferences hosted by Intersolar Europe and EES.

Solar Cell Development and Production Technology

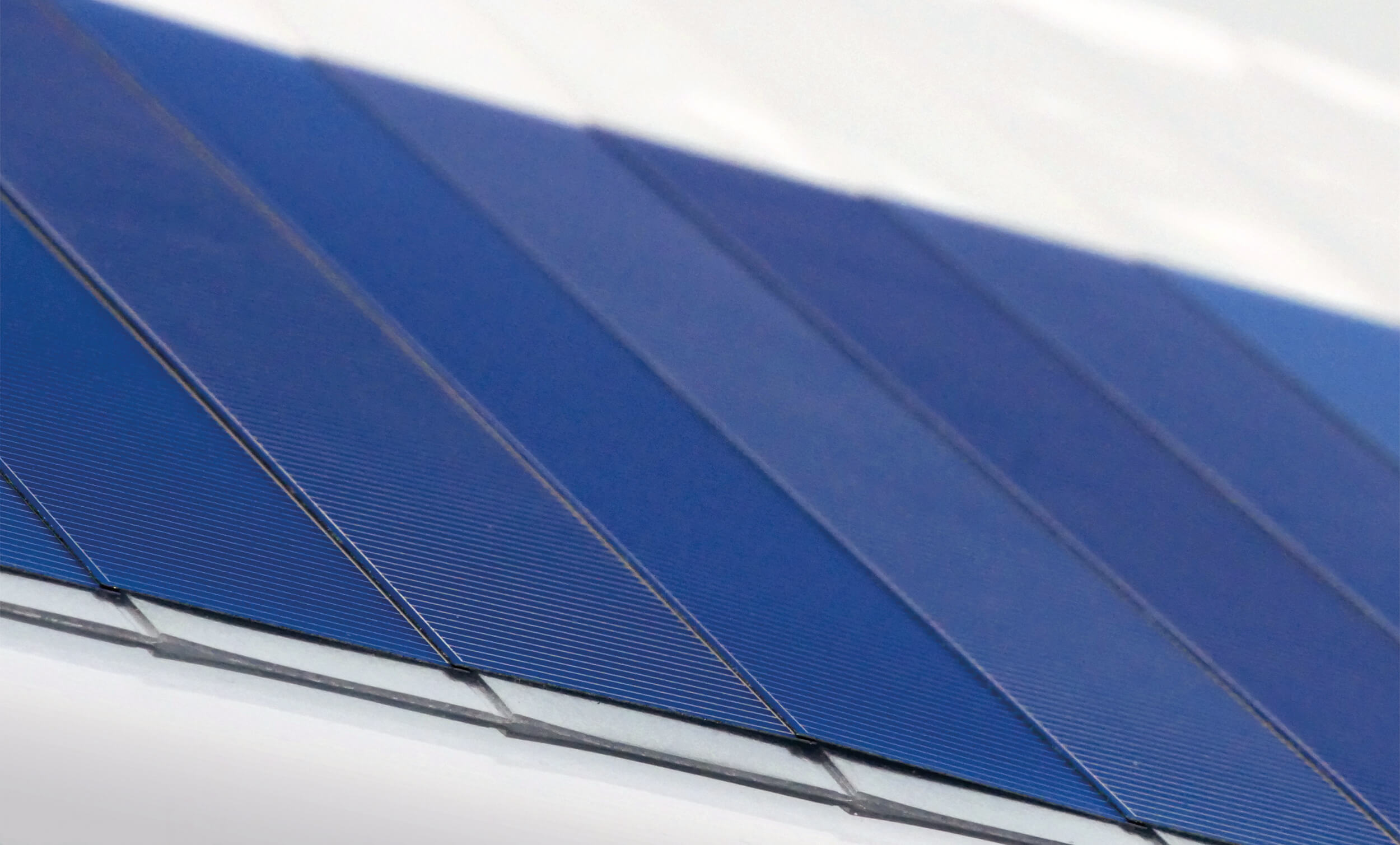

Fraunhofer ISE, based in Freiburg, Germany, is set to present monocrystalline solar cells with an edge length of 22 mm x 148 mm, partially overlapping each other in the module like shingles — a space-saving solution that leads to greater levels of efficiency. This type of cell is particularly suitable for integration into vehicles, for example, where every bit of available space counts. Fraunhofer ISE will be using their booth to showcase both monofacial and — brand new and for the first time — bifacial shingle solar cells.

PERC solar cells with foil metallization (FoilMet) are based on technology developed by Fraunhofer ISE in which aluminum foil is welded to the silicon wafer by means of laser radiation. This simplified manufacturing process for creating rear-side contacts on PERC cells not only boosts efficiency, it is also considerably less expensive than conventional procedures. During the process, individual laser pulses sent through the passivation layer alloy the aluminum film, welding it to the silicon. The contact points establish a mechanical and electrical connection between the foil electrode and the silicon wafer.

A parallel dispensing print head for metallizing standard silicon wafers ensures the homogeneity of the finger structure on the front of the solar cells in this contactless printing process and optimizes material usage by 15 percent. At the same time, the enhanced finger design improves shading on the surface of the wafers. The line widths start at <30 µm at a finger height of up to 20 µm.

Module Development and Integrated Photovoltaics

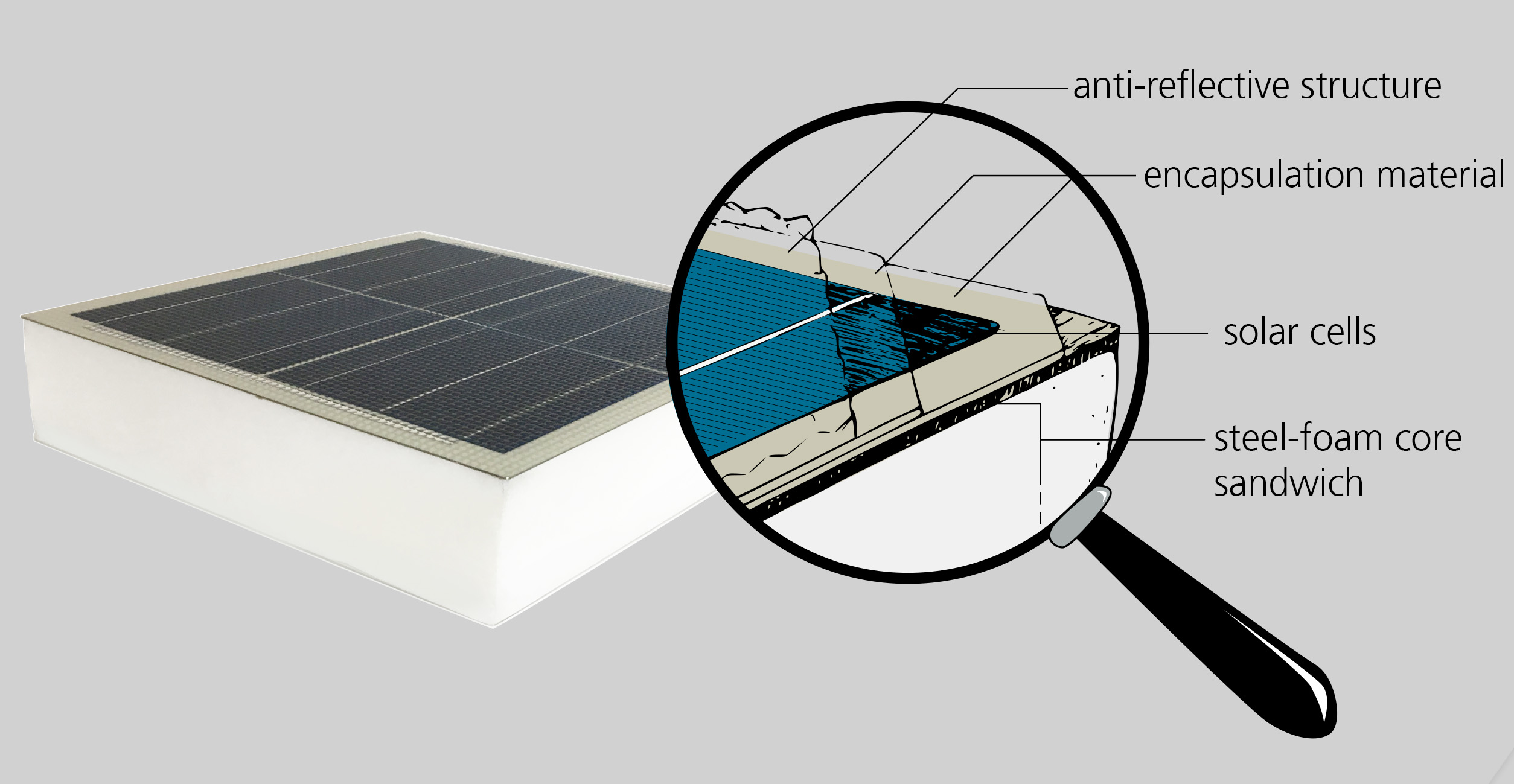

“The consistent increase in installed photovoltaics capacity needed for the energy transition to succeed will not take place solely on roofs and wide open spaces,” says institute director Dr. Andreas Bett. “More and more PV modules will be integrated into buildings, vehicles and road surfaces, as well as elevated installations over agricultural land.” At Intersolar Europe, Fraunhofer ISE will bring module developments for building-integrated photovoltaics (BIPV) to the fore. A decisive factor in achieving this objective is to also offer architects and engineers different design possibilities in terms of façade color while keeping the energy yield losses of PV modules to a minimum. Module developments for integration in vehicles — vehicle-integrated photovoltaics (VIPV) — will also play a key role. Related applications include panoramic roofs for cars or built-in modules for truck roofs to supply power for cooling transported goods.

Solar Forecasting

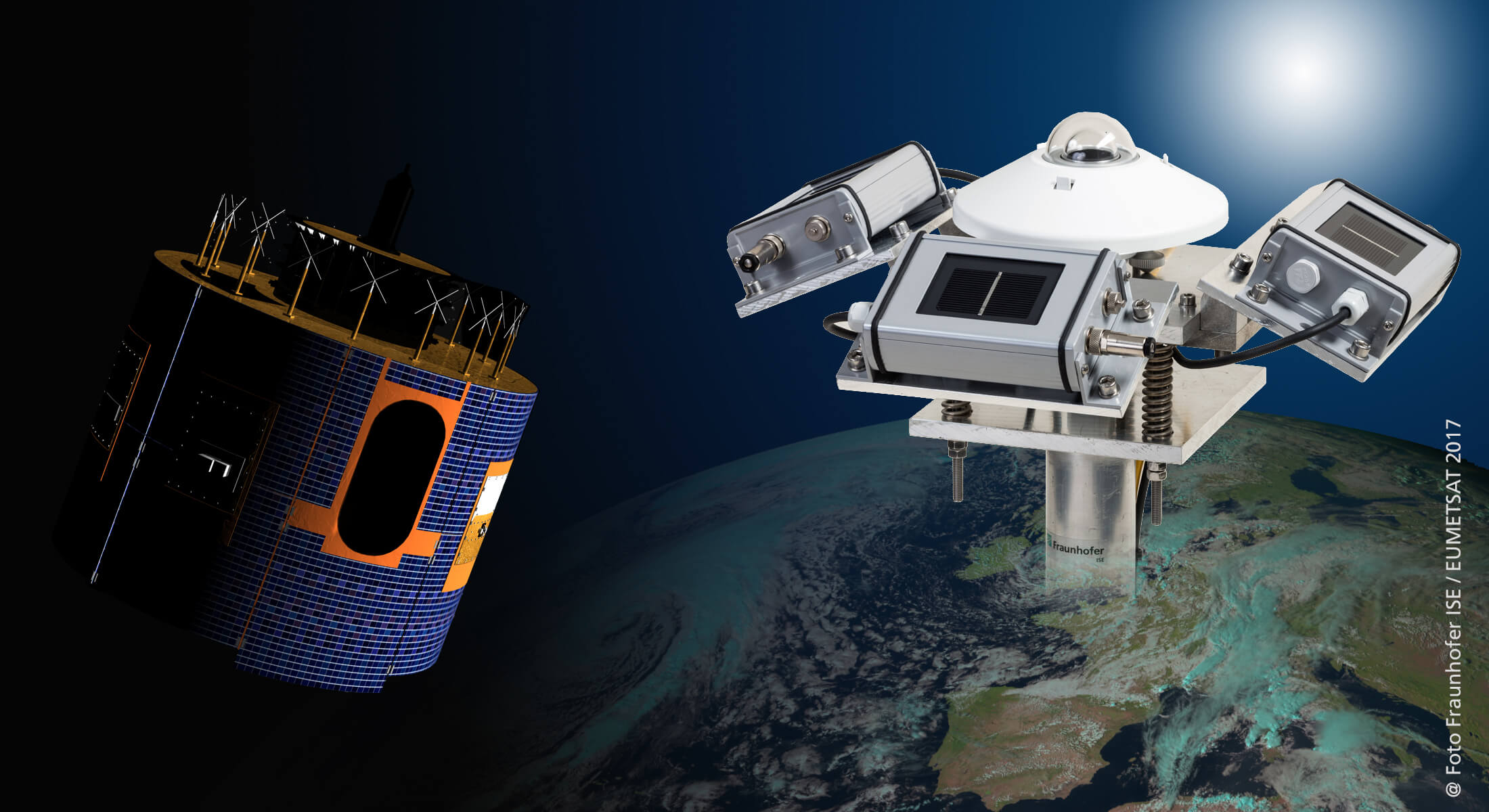

To optimize estimates for PV power yields and therefore the integration of solar energy into the power supply system, Fraunhofer ISE is developing live irradiance sensors. At the exhibition, researchers from the institute will showcase a measuring station that is currently being used in a joint project with partner Transnet BW. This technology is in use at 40 sites across the German State of Baden-Württemberg collecting measurements at one-minute intervals and transmitting the data to Fraunhofer ISE in real time. Combined with simulated PV installation yield data and solar radiation information derived from satellite data, Transnet BW receives solar irradiance data which can then be used to estimate how much solar power will be fed into the power transmission grid.

Detecting Performance Degradation in Modules

PV modules from rear side passivated PERC solar cells are particularly likely to be affected by light and elevated temperature-induced degradation (Le-TID). Unlike light-induced degradation (LID), these modules are at risk of slow-moving yet massive degradation that may lead to full or partial regeneration over a very long-term basis. At the exhibition, Fraunhofer ISE will present one of its in-house developed testing procedures for examining the effects of Le-TID on PV modules.

Power Electronics

The latest developments in the field of power electronics include electronic power connections for battery storage systems as well as control systems for high switching frequencies. At Intersolar Europe, Fraunhofer ISE will exhibit the highly integrated, compact set-up of a three-phase non-galvanically isolated DC/DC converter with silicon carbide MOSFETs, used for connecting a high-voltage lithium-ion battery to the DC intermediate circuit of an inverter.

The institute will also present a central inverter with a modular set-up that is used for a high output of 500 kW and enables parallel connections.

Battery Storage-Based Units and Systems

Fraunhofer ISE has many years of experience in battery systems technology — expertise it is now combining with knowledge of battery development. Both research areas will be represented at its exhibition booth, for instance by a battery stack for stationary applications that is based on aqueous cell chemistry and constructed using sustainable, affordable materials. This flexible architecture can be adapted to specific applications.

Intersolar Europe, Munich, May 15 - 17, 2019

Booth of Fraunhofer ISE: Hall A1.540

Lectures and Conference Contributions by Fraunhofer ISE Scientists:

May 13, 2019

09:00-17:30, ICM

Side-Event: »Power Electronics for Photovoltaics and Battery Systems - Day 1«, Olivier Stalter, Andreas Hensel, Bruno Burger

May 14, 2019

08:30-18:00, ICM

Side-Event: »Power Electronics for Photovoltaics and Battery Systems - Day 2«, Bruno Burger, Felix Eger, Rebekka Denninger, Cornelius Armbruster, Roland Singer

11:30-13:00, ICM

»Ensure Maximum Performance & Reliability of PV Power Plants«, Boris Farnung, Christian Schill

May 15, 2019

09:00-10:30, ICM

»Agrovoltaics - Sharing Resources for Multiple Benefits«, Stephan Schindele, Maximilian Trommsdorff

11:00-12:30, ICM

»Quality Assurance for Products and Projects - Safety, Reliability and Performance«, Matthias Vetter, Adrian Heuer

11:00-11:15, B3.570

as part of The smarter E AWARD: »Smart Renewable District Heating Network with Application of an IoT Webplatform«, Sebastian Herkel and MONDAS

11:00-12:30, ICM

»Utility-Scale PV & Energy Storage - The Best of Two Worlds«, Johannes Wüllner

14:00-15:30, ICM

»Beneath the Panels BOS in Residential Systems«, Bruno Burger

14:45-16:00, C1.550

»Ist eine PV-Fabrik in Deutschland / Europa realistisch?«, Jochen Rentsch

16:00-17:30, ICM

»Beneath the Panels BOS in Utility-Scale Systems«, Bruno Burger

May 16, 2019

10:30-15:30, C2.550

»Nach der Einspeisevergütung: Langfristig rentable Energiespeichertechnologien«, Matthias Vetter