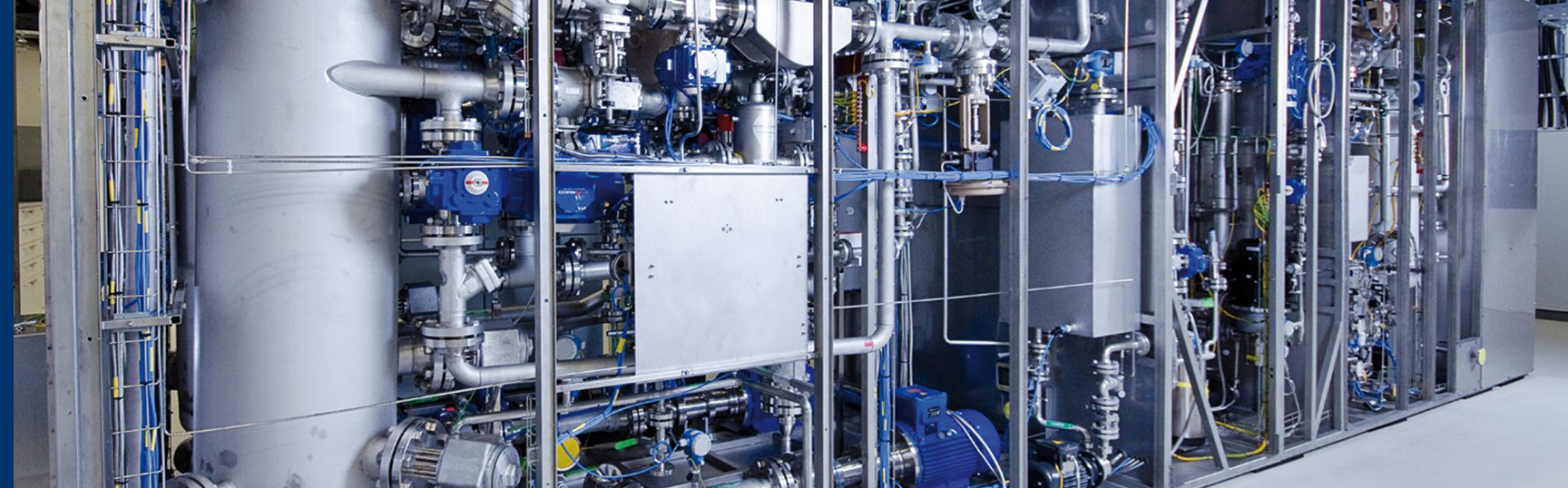

In the context of increasing sector coupling, the conversion of electrical energy into chemical energy plays a crucial role. Fraunhofer researchers are working, for instance, on corresponding power-to-gas processes that enable the chemical storage of energy in the form of hydrogen or methane.