Fraunhofer IGB

CO2 conversion to synthetic fuels and chemicals

Fraunhofer IGB makes the greenhouse gas CO2 usable as a raw material for the chemical industry. With customized catalytic processes from electrochemistry, biotechnology and heterogeneous catalysis, we offer ambitious companies attractive opportunities to use and valorize CO2 streams and to establish renewable value chains.

Our approach: Power-to-X-to-Y

Fraunhofer IGB extends the known Power-to-X approach to the Power-to-X-to-Y concept by further processing the intermediates synthesized from CO2 ("X") in chemical and biotechnological downstream processes to fuels, polymer building blocks, platform and fine chemicals ("Y").

We offer solutions and developments from laboratory to pilot scale as well as technical and economic feasibility studies in the fields of ...

- Synthetic fuels

Processes for fuel synthesis from CO2 via methanol or other alcohols - Power-to-X and biotechnology - profitably combined

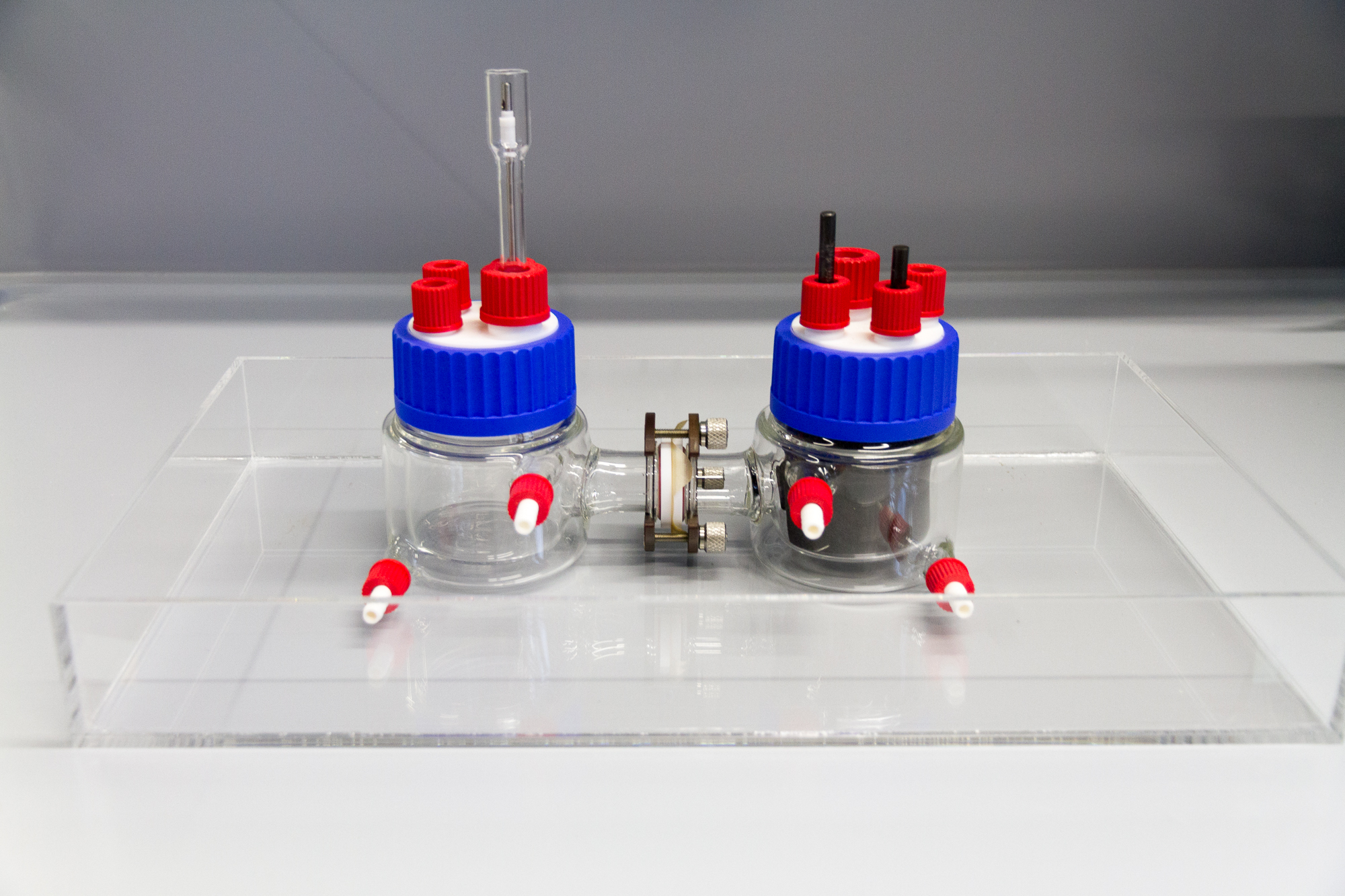

Sustainable and scalable Power-to-X technologies in combination with industrial biotechnology approaches for fermentation of C1 products (methanol, formic acid, etc.) - Electrosynthesis

Electrification of chemistry through direct use of renewable electricity in chemical synthesis for activation of CO2, water or organic substrates - Thermocatalytic synthesis

New processes and catalysts for the production of platform chemicals (methanol, olefins, acrylic acid derivatives, ammonia, etc.) - High-throughput catalyst development and testing

Patented processes for the synthesis of CO2-activating catalysts; catalyst screening in parallelized reactor systems (batch and continuous)