Fraunhofer UMSICHT | Institutsteil Sulzbach-Rosenberg / 2020

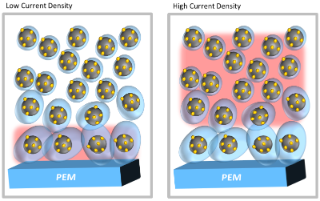

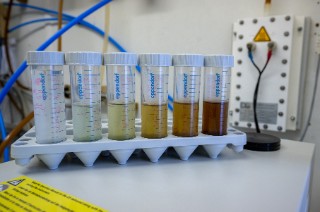

Electrochemical wastewater treatment generates hydrogen

A novel electrochemical purification process for highly contaminated process wastewater is to generate hydrogen at the same time. In the AECO H2+ project, a test stand with electrolysis cell is being set-up to undertake test for industrial use of the technology. The project is carried out by Fraunhofer UMSICHT at its Sulzbach-Rosenberg site with the industrial partners DiaCCon GmbH (Fürth, www.diaccon.de) and Blue Eden CleanTech Inc. (Calgary, Canada, www.blueeden.ca) and is funded within the framework of the Central Innovation Program for Medium-Sized Enterprises (ZIM).

more info